Field Techs from Jenbacher or Service Providers who carry out regular maintenance tasks and repairs on Jenbacher gas engines and who have completed the Basic Development Program. This training is a prerequisite for becoming a certified Service Engineer.

6

6

Mechanical

4 days

Brief Description

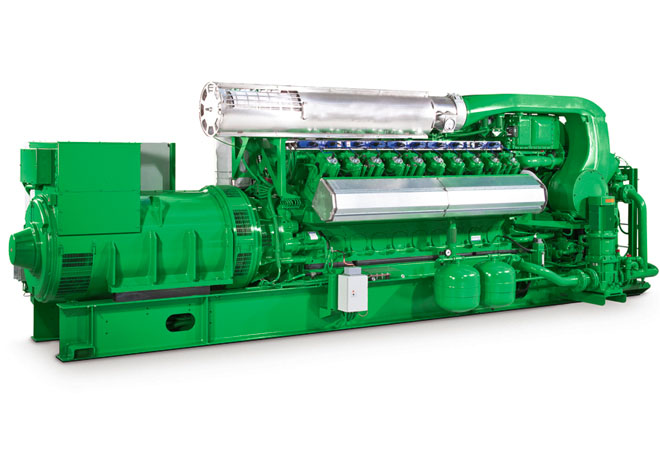

- Advanced training for service engineers who want to carry out minor overhauls of Jenbacher gas engine units.

Target Group

- Field Techs from Jenbacher or Service Providers who carry out regular maintenance tasks and repairs on Jenbacher gas engines and who have completed the Basic Development Program. This training is a prerequisite for becoming a certified Service Engineer.

Theoretical and practical contents

- maintenance - cylinder head (pre chamber, valve spring), cylinder liner

- maintenance - piston (aluminum/steel), piston cooling, connecting rod and bearing

- maintenance - vibration damper, crank shaft seal

- maintenance - crank shaft main bearing and crank shaft thrust bearing

- maintenance - throttle valve (replace throttle valve shaft and bushing, adjustment of throttle linkage)

- maintenance - cam shaft and camshaft bearing and roller tappet guide

- maintenance - gas mixer servo motor and potentiometer

- generator coupling

- spare parts (standard, over- and undersize)

- special tools and hydraulic tools (ITH hydraulic system - excluding disassembling/assembling fly wheel type 6)

- adjustment of the gas train for gas mixer and TecJet® engines

Participation in this training course will give you

- a review of the Basic Development Program

- the ability to carry out necessary maintenance tasks including minor overhaul according to the maintenance schedule

Comments

- Course duration: • 4 days - 26 training units of 60 minutes each

- Number of participants: • Minimum of 5 and maximum of 6 people

- Languages: • German, English

• Other languages on request or with an interpreter

Prerequisites

- FTB - Field Tech Basic or FTB6 - Field Tech Basic Training for Type 6 has to be completed before

- Experience of mechanical engineering

- Knowledge of electrical engineering is recommended

- Participants must bring their own safety boots & working clothes

- Participants should bring a laptop to access online material

Jenbacher Product Training

Jenbacher Product Training