Field Techs for the Jenbacher product portfolio or employees from other departments who need detailed product knowledge for their daily jobs. This training is a prerequisite for the course module ´FTA - Advanced Field Tech Training´ and "MR - Maintenance & Repair Training".

2 , 3 , 4 , 6 , 9 , J624

2 , 3 , 4 , 6 , 9 , J624

General

7.5 days

Brief Description

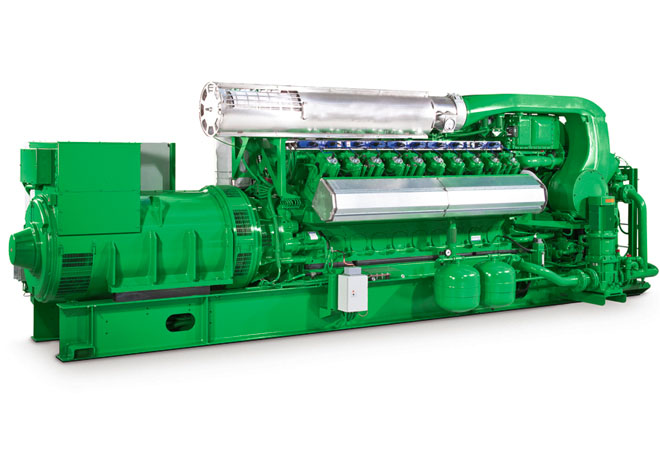

- Basic training for service engineers who want to understand the design, operation and maintenance of Jenbacher gas engine modules.

Target Group

- Field Techs for the Jenbacher product portfolio or employees from other departments who need detailed product knowledge for their daily jobs. This training is a prerequisite for the course module ´FTA - Advanced Field Tech Training´ and "MR - Maintenance & Repair Training".

Theoretical and practical contents

- Engine and engine components (type 2, 3, 4 & 6)

- Operation materials (water, gas, oil, TI's)

- P & ID and wiring diagram (identification of components, gas-, water-, oil- circuit, electrical cabinet)

- Gas train (components, adjustments)

- Engine control system (speed-, power-, island- and LEANOX controller, parameters, gas mixer)

- Engine management system - level 15 (dia.ne versions, tech. Specification, trouble shooting)

- Ignition system (different systems, spark plugs and ignition coils, measurement)

- Knocking (knocking controller, cylinder optimizing)

- Inspection and maintenance works according to maintenance schedule (maintenance schedules, secure engine shut down, special tools, maintenance works at the engine - up to 10.000 OH)

Participation in this training course will give you

- a good overview of the Jenbacher gas engine technology

- an insight into the structure of a Jenbacher gas engine module and terminology for the individual components

- a basic understanding of design criteria for peripheral equipment that is necessary for a CHP plant

- the knowledge required for a successful operation of the Jenbacher gas engine equipment in manual and automatic modes

- the knowledge required to operate the different DIA.NE generations at level 15

- guidance on regular maintenance according to the 10,000 operating hours maintenance schedule

- the ability to adjust and optimize the relevant control loops including adjustment of the LEANOX controller

- the ability to adjust and optimize different gas trains

Comments

- Course duration: • 7.5 days - 49 training units of 60 minutes each

- Number of participants: • Minimum of 5 and maximum of 8 people

- Languages: • German, English

• Other languages on request or through an interpreter

Prerequisites

- Degree in electrical or mechanical engineering

- Participants must bring their own safety boots and working clothes

- bring a laptop to the training

- eTrainings 'pre FTB1, pre FTB2, pre FTB3' and 'dia.ne XT4 basics' must be completed before the training starts (after successful registration, these eTrainings are visible in the My Training area)

Jenbacher Product Training

Jenbacher Product Training